In industrial applications, materials play

a pivotal role in ensuring the efficiency, durability, and cost-effectiveness

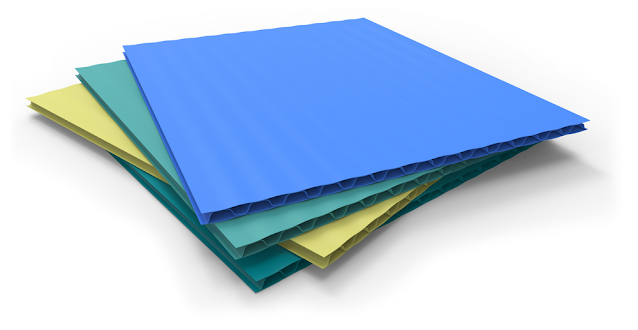

of various processes. One such material that has gained prominence in recent

years is Polypropylene sheet, often

referred to as PP. Polypropylene sheets offer a multitude of benefits that make

them a versatile and dependable choice for a wide range of industrial purposes.

In this blog, we will delve into the top 5 benefits of using PP sheets in

industrial applications.

1. Chemical Resistance

One of the primary advantages of using PP

sheets in industrial settings is their remarkable resistance to a wide array of

chemicals. Polypropylene is inherently non-reactive to most acids, bases, and

organic solvents, making it an ideal choice for industries where exposure to

corrosive substances is common. This chemical resistance ensures the longevity

of the material and reduces the risk of degradation, maintaining the integrity

of the equipment and structures where PP sheets are used.

2. High Temperature Tolerance

Polypropylene

sheets are known for their ability to withstand

high temperatures without deformation or loss of mechanical properties. This

thermal stability is crucial in industries where extreme heat is a common

occurrence. PP sheets can endure temperatures of up to 160°C (320°F), making

them suitable for applications such as chemical processing, food manufacturing,

and more. Their dimensional stability at high temperatures ensures that the

desired performance and structural integrity are maintained even under adverse

conditions.

3. Lightweight and Durable

Polypropylene sheets are exceptionally

lightweight yet robust, making them easy to handle and transport while still

offering substantial strength. Their high impact resistance and flexibility

make them a durable choice for a variety of industrial applications. PP sheets

can absorb and dissipate energy, reducing the risk of damage in high-impact

scenarios, further contributing to their longevity.

4. Easy to Fabricate

Polypropylene

sheets are known for their ease of fabrication.

They can be cut, welded, and thermoformed with relative ease, allowing for the

creation of customized components and structures tailored to specific

industrial needs. The versatility of PP sheets in terms of processing and

forming ensures that they can be adapted to a wide range of applications, from

storage tanks and pipes to intricate machine parts.

5. Low Maintenance and

Longevity

Another notable benefit of using PP sheets

in industrial settings is their low maintenance requirements. Their resistance

to chemicals and UV radiation, combined with their durability, ensures a longer

service life with minimal upkeep. PP sheets are less prone to corrosion, and

their smooth surface prevents the buildup of dirt and contaminants, reducing

the need for frequent cleaning or repairs. This characteristic not only saves

time and money but also contributes to the overall cost-effectiveness of using

Polypropylene sheets in industrial processes.

Conclusion

Polypropylene sheets have become an indispensable material in

various industrial applications due to their outstanding qualities. Their

resistance to chemicals, ability to withstand high temperatures, lightweight

yet durable nature, ease of fabrication, and low maintenance requirements make

them a preferred choice for industries ranging from chemical manufacturing to

food processing. By incorporating PP sheets into their processes, industries

can achieve cost savings, improved efficiency, and increased reliability,

ultimately reaping the benefits of this versatile and dependable material.

Discover

the future of industrial solutions with AKMY Polyplast, the best polypropylene sheet manufacturer in India.

Our high-quality polypropylene sheets are the answer to your material needs.

Explore our product range and experience the difference in quality, durability,

and versatility. Contact us today to discuss how AKMY Polyplast can elevate

your industrial projects.