LED light panels have become increasingly popular in recent years, and for good reason. They provide an energy-efficient, long-lasting, and versatile lighting solution for a wide range of applications. One of the key features that make LED light panels so useful is their LGP or Light Guide Panel. In this blog post, we will explore what LGP is and why you need it in your LED light panel.

What

is LGP Sheet?

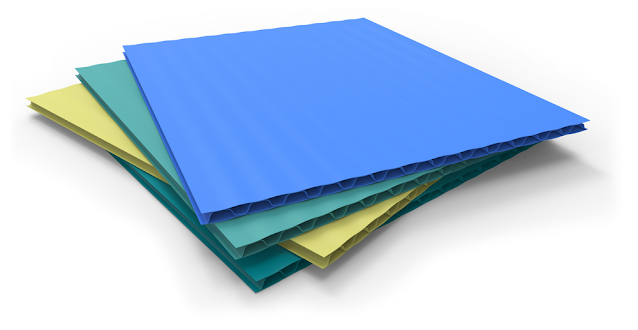

LGP stands for Light Guide Panel, which is

a flat sheet, made of transparent plastic material, usually acrylic or

polycarbonate. The LGP Sheet is used to distribute the light evenly across the

surface of the LED light panel, ensuring that the light output is uniform and

bright. The LGP is positioned in front of the LED light source and acts as a

diffuser, scattering the light in different directions and spreading it evenly

across the panel surface.

Why

is LGP important in LED light panels?

There are several reasons why LGP is

crucial in LED light panels:

- Uniform illumination: LGP is essential

for ensuring that the light output from the LED panel is uniform and evenly

distributed. Without an LGP, the light output would be concentrated in certain

areas, resulting in hotspots and dark spots on the surface of the panel. This

uneven illumination can make it difficult to see objects clearly and can also

cause eye strain and fatigue.

- Improved aesthetics: LGP

Sheet can enhance the appearance of LED light panels by creating a

sleek, modern look. The LGP diffuses the light, making it appear softer and

more natural, which can be especially useful in applications where the lighting

needs to be aesthetically pleasing, such as in retail displays, art galleries,

and museums.

- Energy efficiency: LGP can improve the

energy efficiency of LED light panels by reducing the number of LEDs required

to achieve the desired level of illumination. Since the LGP diffuses the light,

it allows for greater coverage area with fewer LEDs. This can result in

significant energy savings and lower operating costs over time.

- Longevity: LGP Sheet can extend the

lifespan of LED light panels by reducing the amount of heat generated by the

LEDs. The LGP helps to dissipate the heat, which can help to prevent premature

failure of the LEDs and other components in the panel.

What

are the different types of LGP?

There are several different types of LGP

available, each with its own unique properties and benefits. Here are some of

the most common types:

- Acrylic LGP: Acrylic is the most common

material used for LGPs due to its high transparency, excellent light

transmission, and ease of fabrication. Acrylic LGPs are typically less

expensive than other materials and are available in a range of thicknesses,

from 2mm to 10mm.

- Polycarbonate LGP: Polycarbonate LGPs

are known for their exceptional durability and impact resistance. They are

often used in applications where the panel may be subject to rough handling or

impact, such as in transportation or outdoor signage.

- Glass LGP: Glass LGPs offer superior

optical clarity and are often used in high-end applications where the highest

quality lighting is required, such as in luxury retail displays or museum

exhibits. However, glasses LGPs are typically more expensive than other materials

and can be heavier and more difficult to work with.

Overall,

LGP

Sheet is an essential component of LED light panels that helps to

ensure uniform illumination, improve aesthetics, increase energy efficiency,

and extend the lifespan of the panel.

AKMY

Polyplast is one of the leading LGP sheet manufacturers in India. AKMY Polyplast specializes in the production

of LGP sheets and offers a wide range of products that are suitable for

different applications. With its state-of-the-art manufacturing facility and

team of experienced professionals, AKMY Polyplast is well-positioned to meet

the growing demand for high-quality LGP sheets in India and beyond.

.png)