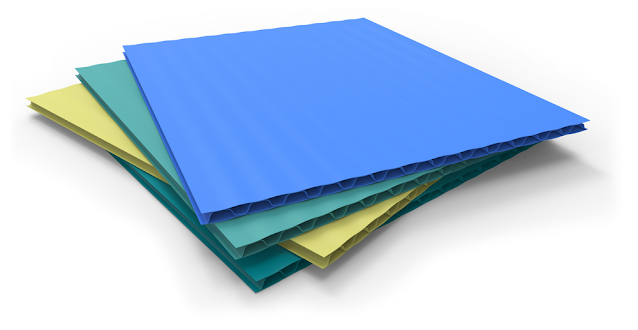

Polypropylene sheet is a material with a wide range of applications. It is ideal for creating outdoor advertising signs for a business or event. It can be used in construction, packaging, protecting other materials, and as a barrier against water. These are only a few of the many uses it has. Numerous industries make use of polypropylene.

Polypropylene may already be widely used in

your industry, but what do you know about its properties as a material? There

are a few properties of polypropylene that you should be aware of if you want

to use it for coating wire, as a packing material, or for a variety of other

purposes. Knowing these properties will help you decide how best to use it for

your business.

Strength

Its structure gives polypropylene sheet a

respectable amount of elasticity—roughly 4,800 psi. Despite the material's

light weight, this number indicates that it can withstand significant pressure

or loads. One of the reasons polypropylene is an excellent material for

packaging is this property.

Water

Absorption

Polypropylene sheet roll can be a great material to use in a wet environment due to its

ability to absorb water. Polypropylene absorbs less than.01 percent of its

weight in soak tests. Because of this, polypropylene is ideal for total

immersion applications in which the material in the basket below must be protected

from various chemicals.

Temperature

Resistance

Polypropylene can operate at a maximum

temperature of 180 degrees. Although this number indicates that it is not

appropriate in extremely hot situations, it is suitable for the majority of

outdoor applications, such as making outdoor signage. Polypropylene won't work

as well at temperatures higher than 180 degrees, but it won't melt until 327

degrees.

Hardness

Polypropylene sheet roll is a good material for applications requiring some flexibility

because it is not particularly hard. It is somewhat flexible and may be bent

without losing its shape. It rates at the top end of the softer materials

tested on the Rockwell R scale, at 92, which places it on the scale. It denotes

that the substance is somewhat stiff. Because of this, it will probably flex

and bend when hit.

Chemical

Resistance

Similar as with water, polypropylene has a

high protection from synthetic substances, particularly when contrasted with

polyethylene, another plastic usually utilized. Polypropylene is a great choice

for applications involving a lot of acids, organic solvents, or alkaline to

avoid absorption.

If you’re looking for polypropylene sheet manufacturers

in India for your project, get in touch with AKMY Polyplast.

Co-extruded polypropylene sheets with UV coating in plain, textured, and fabric

designs are produced by AKMY Polyplast. They offer the broadest selection of

polypropylene sheets, including clear, opal, green, blue, brown, and orange

varieties. They also provide the broadest selection of polypropylene sheets

with textures and designs, like Diamond, Embossed, Badal, Rainbow, Bamboo, and

Leather in a variety of colors and thicknesses. AKMY Polyplast’s polypropylene sheets come in more than 15 different option ranges and many more

fabric/clothes styles.