LED light diffuser sheets and acrylic boards are two materials commonly used in lighting applications. While they may seem similar at first glance, there are actually several key differences between the two. Understanding these differences can help you choose the right material for your specific lighting needs.

What

is an LED Lighting Diffuser Sheet?

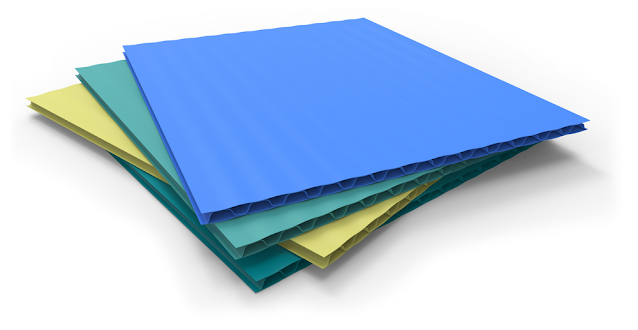

An LED lighting diffuser sheet is a thin,

translucent material that is designed to diffuse light evenly across a surface.

These sheets are commonly used in applications where a soft, diffused light is

desired, such as in backlit signs or displays, light boxes, and architectural

lighting.

LED light diffuser sheets are typically

made from a polycarbonate or acrylic material that has been specially treated

to scatter the light passing through it. This scattering effect helps to

eliminate harsh shadows and hot spots, creating a more even and aesthetically

pleasing light output.

What

is an Acrylic Board?

An acrylic board, also known as a

plexiglass or acrylic sheet, is a clear or colored plastic material that is

commonly used as a substitute for glass. Acrylic boards are lightweight,

shatter-resistant, and more durable than glass, making them a popular choice

for a wide range of applications.

In lighting applications, acrylic boards

are often used as a protective cover for LED lights, as they can help to

protect the lights from dust, debris, and other environmental factors. They can

also be used to create colored or textured lighting effects, such as in

architectural lighting or artistic installations.

Differences

Between LED Lighting Diffuser Sheets and Acrylic Boards

While both LED lighting diffuser sheets and

acrylic boards are used in lighting applications, there are several key

differences between the two materials. Here are a few of the most significant

differences to consider:

- Light Transmission

One of the biggest differences between LED

lighting diffuser sheets and acrylic boards is their light transmission

properties. LED lighting diffuser sheets are designed to scatter light evenly

across a surface, whereas acrylic boards allow light to pass through with

little to no scattering.

This difference in light transmission properties

means that LED light diffuser sheets are better suited for applications

where a soft, diffused light is desired, such as in backlit signs or displays.

Acrylic boards, on the other hand, are better suited for applications where a

clear, unobstructed light is needed, such as in protective covers for LED

lights or in colored lighting effects.

- Material Composition

LED lighting diffuser sheets are made from

a variety of materials, including polycarbonate, acrylic, and PET. In contrast,

acrylic diffuser boards are made exclusively from PMMA.

- Durability

Another key difference between LED

light diffuser sheets and acrylic boards is their durability. LED

lighting diffuser sheets are typically made from a polycarbonate or acrylic

material that has been specially treated to scatter light. While these materials

are durable, they are not as strong or impact-resistant as acrylic boards.

Acrylic boards are much stronger and more

impact-resistant than LED lighting diffuser sheets, making them a better choice

for applications where the material may be subject to physical stress or

impact. They are also more resistant to weathering and UV damage, making them a

good choice for outdoor lighting applications.

- Clarity

The clarity of the material is another

important difference between LED light diffuser sheets and acrylic

boards. LED lighting diffuser sheets are designed to scatter light, which can

make the material appear cloudy or hazy. This effect is intentional, as it

helps to eliminate harsh shadows and create a more even light output.

Acrylic boards, on the other hand, are

designed to be clear and transparent, with minimal distortion or cloudiness.

This makes them a good choice for applications where a clear, unobstructed

light is needed, such as in protective covers for LED lights or in

architectural lighting.

- Cost

Acrylic boards are generally less expensive

than LED lighting diffuser sheets. This makes them an attractive option for

budget-conscious lighting projects.

- Application

LED diffuser sheets are

ideal for applications where it is desired to reduce glare and create a softer,

more diffused light output. Acrylic boards, on the other hand, are highly

versatile and can be used in a wide variety of lighting applications.

Conclusion

Overall, understanding the differences

between LED diffuser sheet and acrylic board is essential for anyone

who wants to achieve optimal lighting results. While both materials have their

unique benefits, LED light diffuser sheets are more preferred for their superior

light distribution capabilities and ability to prevent glare. They are also

more durable and scratch-resistant than acrylic boards, making them an ideal

choice for high-traffic areas. On the other hand, acrylic boards are more

cost-effective and easier to work with than LED lighting diffuser sheets. They

are also versatile and can be used in a wide range of applications, from

signage to displays and even furniture.

.png)